It seems we are increasingly in the age of the ‘cookie-cutter’ kart.

It appears there has been a convergence of design from the main kart manufacturers, and the layout of the various chassis now appear to be rather homogenous. And that’s because the current configuration works – even if it can be a bit of a black art to fine-tune on race day.

But not every brand is manufactured to this formula. American constructor Track Kart (or TracKart as it is on the stickers) is one example.

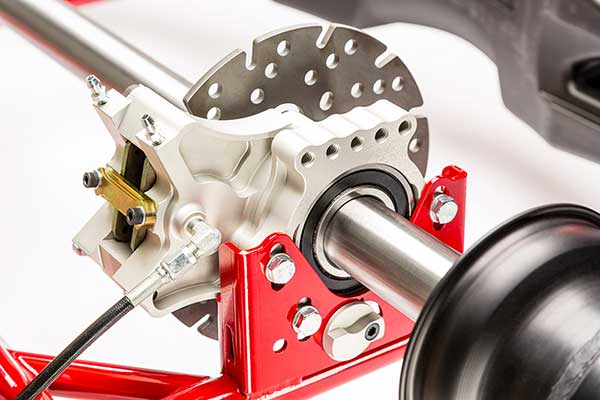

The USA-built TracKart Hammerhead 4C is an A-frame design using 30mm tubing, 40mm axle and 17mm front stubs.

While the A-frame layout is not new, it has been out of fashion with the big Euro manufacturers for many years. But it can work, as proven by Australian manufacturer Omega who have had much success with theirs over the years.

What’s unique about the Track Kart version are the replaceable tubes running from the C-section back to the main rails (this has usually been a permanent welded piece on other brands), the adjustable seat mounting and the method of independent camber and caster adjustment.

“I have been building karts for six years, mostly two or three at a time, but occasionally 15 to 20 karts at once” Track Kart’s Jeremy Warren told KartSportNews.

“The majority of the components I make in house, with exception of the seat, steering wheel, bodywork, and wheels. I design, build, test, and race the karts myself.”

In 2016 Warren branded his creations ‘Track Kart’.

“I have been working on products for the Briggs LO206 market” he explained.

“The kart shown here is for the Briggs class and I also build 2-cycle karts as well” (Track Kart’s Hammerhead 2C chassis is for 100cc and 125cc classes. It has a 30mm tube chassis with 50mm rear axle and 25mm stubs.)

“My karts have been successful in the USA and I am working on a Cadet chassis to have a nice product line up.”