Karting Australia will now allow the IAME KA100 engine to have its crankshaft main bearing journals hard-chromed.

The process allows worn cranks to be restored to factory measurements without having to replace them. It was a technique commonly used on the popular Yamaha KT100S.

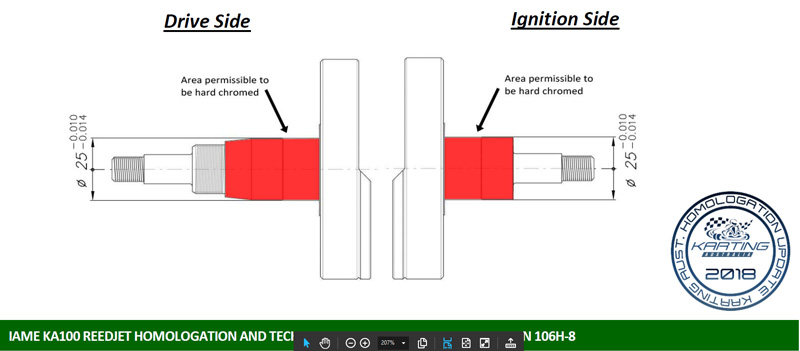

KA Homologation Update Bulletin 106H-8 specifies the areas that can receive the treatment, plus maximum dimensions for the hard chrome.

EXPLANATORY NOTES SUPPLIED BY THE MANUFACTURER:

The KA100 engines have been in use in Australia since early 2015 and many are reaching the hours of use where the crankshaft bearing journals and sealing surface may be worn beyond the optimal tolerance, therefore necessitating the replacement of the crankshaft.

If desired, as a more cost-effective option, it is permitted to Hard Chrome the worn surface to restore the crankshaft to the original factory tolerances.

This will allow the usable life of the component to be extended at a significantly reduced cost to the end user while providing a more durable wear surface.

The process of Hard Chroming would not result in any performance advantage in comparison to a new component, as the surface is just being renewed to the original specification to regain the optimal clearance between the crankshaft, main bearings and crank seals.

The Homologation Update Bulletin identifies the only areas of the crankshaft that are permitted to be Hard Chromed and the maximum permitted dimensions of the Hard Chroming that is allowed.

- Download the original PDF from the KA website HERE.